A Strain gauge(resistance strain gauge) is an important type of resistance transducer whose resistance varies with applied force. It can be used to convert force, pressure, tension into a change in electrical resistance. The applied strain can be measured by this change in resistance.

Basic Principle

We know that the resistance of a conductor is given by

Where ρ is the specific resistivity, L is the length and a is the area of cross-section of the resistance material.

When this material is under a strain, the resistance R will change because of the change in L, a or ρ.

Gauge factor

The gauge factor of a strain gauge is defined as the unit resistance change per unit strain. The resistance change is due to the change in length, the change in the area of cross-section and the change in resistivity(piezoelectric change). The sensitivity of a strain gauge is expressed in the gauge factor.

The strain that is applied to the gauge can be determined by the gauge factor and by the measure of the resistance change.

Gauge factors of different gauge materials are given in the table.

| Grid Material | Composition | GF |

|---|---|---|

| Nichrome | 80% Ni, 20% Cr | +2.0 |

| Constantan | 45% Ni, 55% Cu | +2.0 |

| Isoelastic | 36% Ni, 8% Cr, 0.5% Mo, remaining Mn,Fe and Si | +3.5 |

| Iridium-Platinum | 5% Ir, 95% Pt | +5.10 |

Types of Strain gauges

Based on the construction method used strain gauges are classified as

- Unbonded type

- Bonded type

Based on the type of resistance material strain gauges can be classified into

- Fine wire strain gauge

- Metal foil strain gauge

- Semiconductor strain gauge.

- Photo-electric strain gauge

Unbonded type Strain gauge

A strain gauge which is not directly bonded on the surface under study is called an unbonded type strain gauge. It has two frames P and Q with fixed insulated pins as shown in the figure. These two frames are held together by a string loaded mechanism and they can move relatively with respect to each other. A fine wire is stretched around the insulated pins. To measure the strain, the gauge is connected to a Wheatstone bridge.

When a force is applied on the frames, frame P moves relative to frame Q, and the length and area of cross-section of gauge will change, due to this strain. This strain changes the resistance of strain gauge and this change in resistance is measured using a Wheatstone bridge. It can be analysed to measure the applied force and change in dimension of the structure under study.

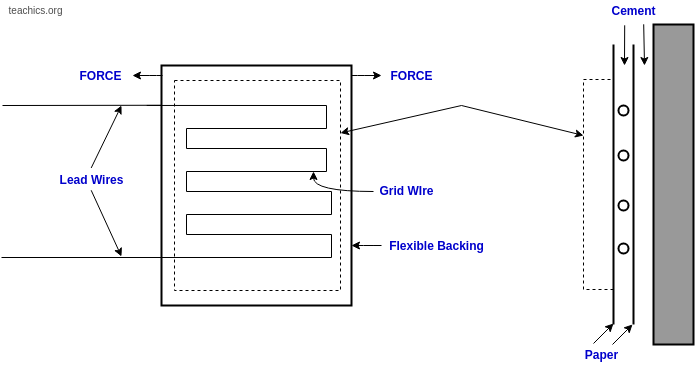

Bonded type Strain gauge

These strain gauges are directly bonded on the surface of the structure under study.

A fine resistance wire is made into a form of a grid and is cemented between the carrier. Resistance wire with a high gauge factor is chosen. The wire is spread so that the stress is uniformly distributed over the grid.

The carrier material should have high mechanical strength and good adherence to cement used. For this purpose, a thin sheet of paper, Bakelite, Teflon sheet are commonly used. it is covered on top with a thin sheet of material and this prevents the wire from any mechanical damage.

The carrier is bonded with an adhesive material and due to this, a good transfer of strain from carrier to a grid of wires is achieved.

Fine wire strain gauge

A fine wire strain gauge is a type of bonded strain gauge. Resistive wire is bent like a string and is packed in a plastic or paper bag. When a force is applied, the wires change in dimension and the resistance is also changed. These change in resistance is analysed to measure the applied force. Metal components like Nichrome, Constantan are used as resistance materials.

Fine wire gauges have high accuracy and high reliability but it is costly.

Metal foil strain gauge

A metal foil strain gauge is constructed by printing a resistive metal foil on a nonelectrical base material such as PCB. When a force is applied, the gauge will undergo a change in both length and area of cross-section resulting in the change in resistance.

Advantages

- Perfect binding is possible with the structure under study.

- Can be manufactured in any shape.

- Good sensitivity and stability even in high temperature.

- Long life.

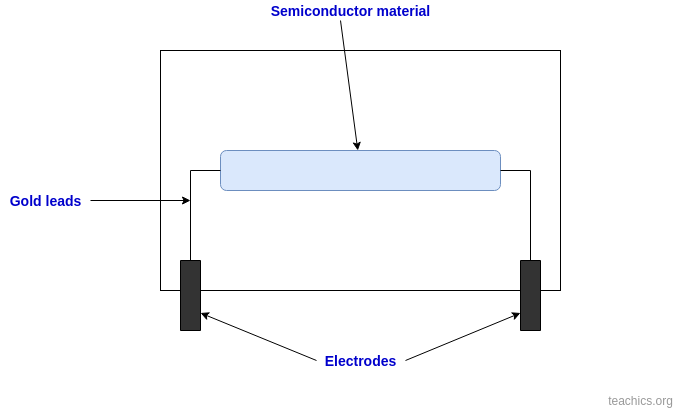

Semiconductor strain gauge

Semiconductor strain gauges make use of the piezoelectric property of the semiconductors such as silicon and germanium. It is used where a high gauge factor is required. It is constructed by bonding semiconductor filaments to a suitable insulating surface. They are very sensitive to temperature changes. But increasing doping decreases sensitivity towards temperature as well. For electrical contact, Gold leads are usually used.

When the strain is applied, the filament undergoes a large change in resistance and this change in resistance can be analysed to measure the strain applied.

Advantages

- High gauge factor.

- Can be used for measuring small strains.

- Long life and high durability.

Disadvantages

- Sensitive to change in temperature.

- Difficult to attach with the structure.

- Costly.

Photo electric strain gauge

A photoelectric strain gauge generates an electric current which is proportional to the applied strain by using a photocell detector, two fine gratings and a light beam. This type of strain gauges is not commonly used. They are delicate and expensive.